The efficiency of the production process, the quality of the output, and the competitiveness of the enterprise in the market are all affected by the type of card punching machine selected in the card making and filter paper production industries. The production demand for high-precision poker components and filter paper is large, and poker card punching machines are needed to ensure production demand. As a global distributor of card punching machines, with practical experience of tens of millions of production capacity, focusing on the five attributes of "precision, durability, multi-function, intelligence, and customization," it provides accurate machine selection assistance by understanding the selection needs of enterprise customers in a targeted manner.

Burr-free production and precise punching with punching machines

The ability to produce card punching machines with burr-free edges and micron-level precision is the standard for card punching machines and the difference between competitors in the mid-to-high-end market. The cards produced by inferior game card punching machines have rough edges and poor hand feel, and the printed images may be misaligned. Inconsistent filter paper pore size will affect the filtration process. Quality issues like this can lead to loss of customers and business. We understand the importance of machine service quality and customer satisfaction.

Materials of the same material can be processed with different stamping speeds and pressures. For example, for materials such as paper and film, advanced stamping technology is used to avoid damage, while for harder plastic and wooden cards, the pressure is increased to achieve a flat processing effect. One European publisher of game cards said that the pass rate of its game cards increased from 89% to 99.7%, and the rework cost decreased by 60%. This precision applies to other products such as oil filter paper or steamer paper, where each filter paper and pore size are uniform. They also meet food and industrial grade standards.

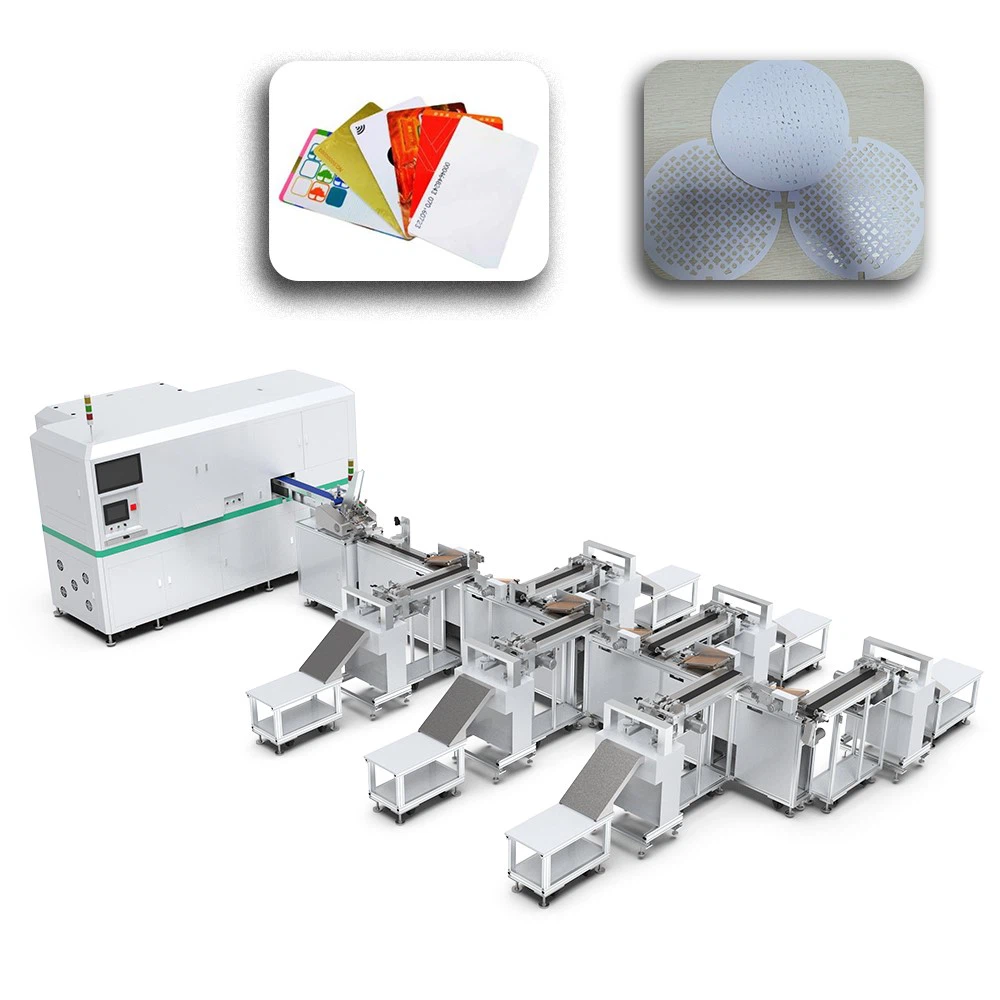

Integrated multi-function punching and cutting machine

Faced with rising manufacturing costs worldwide, companies have had to use one machine for multiple purposes. This is to reduce costs and improve productivity. When the filter paper punch and the card punch are used separately, the space, initial cost, and labor cost increase linearly. This has already been achieved on our card punch. We have achieved the necessary and significant reduction in the number of face machines required to produce a variety of paper types and shoulder machine types.

The cutter can efficiently switch between card and filter paper production. In card production mode, the machine can handle a variety of cards, such as game cards, membership cards, and smart cards. In addition, it is suitable for paper products, including calendar inner pages, books, brochures, file bags, and envelopes. When switching to filter paper production, it can accurately handle coated and uncoated filter paper. Most notably, the equipment can be equipped with a hot stamping process module to meet the personalized processing needs of greeting card companies and cultural and creative product designers. It can realize the integrated production of "stamping + hot stamping." Moreover, the die-cutting machine also includes sorting and classification, which can replace the work of 3-5 manual sorters. This is an economic advantage for companies, as recent studies of the equipment have shown that it helps increase daily production by 30% and reduce labor costs by 40%. This high level of automation is designed for the various production needs of the cultural and creative industries, as well as printing and design companies.

Parameter analysis of punching machine

The functionality of the punching machine is reflected by the parameters, which must be combined with their own production capacity scale and product characteristics. The parameters here refer to the core parameters necessary for production. There are three main categories of core parameters. First, the power parameters, which determine the upper limit of production capacity. The 7.5 kW servo motor can punch 12,000 cards per hour when working continuously for 24 hours, meeting the production needs of large card and filter paper manufacturers. The second type is adaptive parameters, which determine the scope of application of the equipment. The equipment can adapt to various materials, such as paper or plastic fiber sheets, with a thickness ranging from 0.1 to 5 mm, a width of up to 600 mm x 800 mm, and special-sized materials such as postcards and large brochures. Intelligent parameters determine production efficiency. The PLC registration control system of the equipment can digitally store more than 1,000 sets of production parameters in the equipment. When switching products, the parameters can be instantly called up, and the mold changing time is shortened from 40 minutes of the traditional equipment to 5 minutes.

The durability and distinct texture of the cutter are also its prominent features. The body is made of high-strength alloy material, and the wear resistance is increased by 3 times after quenching treatment. Under normal maintenance, the service life of the equipment can reach more than 10 years, which is much higher than the industry average of 5 years. A Japanese cultural and creative enterprise reported after using the equipment for five years that the equipment failure rate was less than 0.3% and the maintenance cost was only 1/3 of that of similar products.

Customized solutions and service guarantee

In the context of diversified global market demand, customization capabilities and service guarantees have become important bonus points for selection. We provide integrated customized solutions, from early-stage capacity planning and equipment parameter customization to later-stage installation and commissioning and full-process services for personnel training. In response to the demand for finished product collection, two modes of collection, in order and collection by category, can be customized to meet the different needs of greeting card companies for sorting by style and printing plants for sorting by batch.

The Shenzhen-based company started in Shenzhen and has established local service points in more than 20 countries around the world. For overseas customers, we provide a 48-hour response service. Whether you are a filter paper manufacturer in Southeast Asia who needs equipment debugging or a card developer in North America who needs parameter optimization, the localized service is efficient and convenient. The advancement of technology and service has enabled the export of equipment to more than 30 countries in Europe, North America, Southeast Asia, etc. More than 1,200 companies around the world see us as a trusted partner.

In short, when choosing a card punching machine, the "five major focuses" of "accuracy, versatility, adjustable parameters, robust structure, and adaptability" should be considered. In addition, the company's product type, production scale, international service needs, etc. should also be considered. This Shenzhen-made die-cutting machine, with its 7.5 KW servo motor, multi-function integration, full-scene customization, and other advantages, serves global customers, including poker manufacturers, printing plants, filter paper manufacturers, etc. Choosing the right die-cutting machine is not only an upgrade of production technology but also a strategic move for enterprises to consolidate their competitive position in the global market.